MANUFACTURING MANAGEMENT & BUSINESS CHALLENGES

Outdated management, hindering business development

Modern manufacturing management model

Business challenges

Challenges

1. Can the company take the new customer order with current capacity ?

2. Why is production planning always slow and takes too much time ?

3. Will the order scheduled for delivery in two days be on time? If late, by how many days?

4. Where is the production progress for customer A’s order ?

5. Are current materials enough for the next delivery batch ?

Reason

1. The company’s production capacity includes: machinery, labor, molds, etc.

2. Production planning is mainly done manually, without support tools.

3. Production process for each product, and material consumption norms for each stage.

4. Production progress, product quality, delivery schedule.

5. Raw material inventory and the supply capacity of suppliers.

1EMS-ERP - Specialized management for Manufacturing

Integrated, comprehensive, optimized for Omnichannel Retail Model

1. The Enterprise management information layers

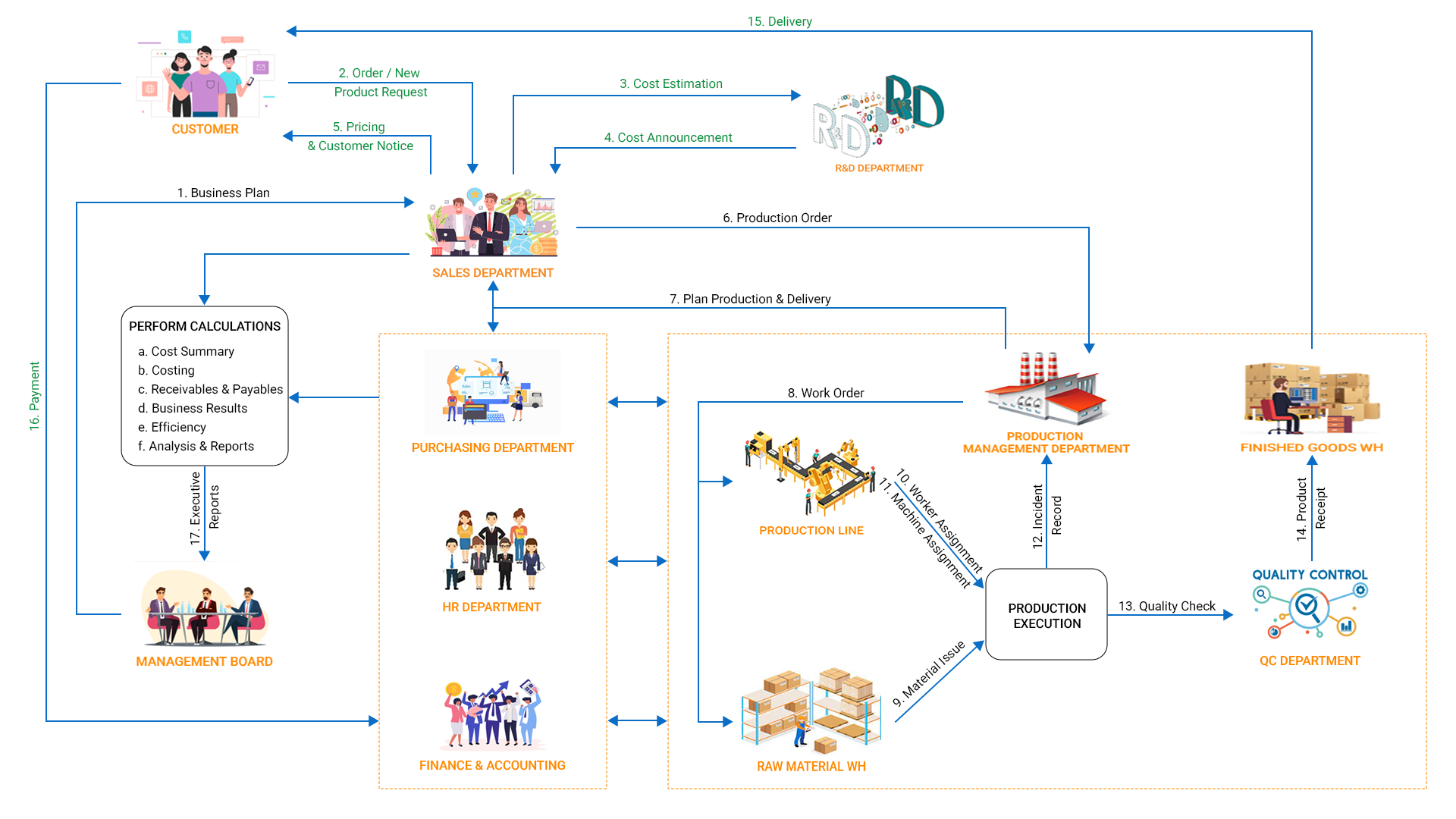

2. 1EMS-ERP Overview

1EMS-ERP is your all-in-one management platform that automatically integrates and connects data across all departments, delivering the accurate, real-time insights leadership needs for decisive action. The system is enhanced with AI and Biometric technology, ensuring accessible management across Windows, Website and Mobile

3. You will solve management problems with 1EMS-ERP

4. 1EMS-ERP implementation process

Clear, scientifific, practical

1 Preliminary survey and overall assessment through work.

2 Quotation, negotiation, and contract signing.

3 Detailed survey of all related activities.

4 Discussion and consensus on each business process.

5 Adjusting the system to meet the agreed process.

6 System configuration, installation, and testing.

7 System re-adjustment if there are any inadequacies.

8 User training on system usage.

9 Cleaning and updating catalogs and opening data.

10 Application, contract acceptance, liquidation, and warranty.

Infrastructure for 1EMS-ERP System

Depending on the scale and requirements, the business can use one of the following two methods to deploy the infrastructure to run 1EMS-ERP.

Rent a server on the cloud.

Self-equip a dedicated server for the business

Warranty - Maintenance

- We will perform system warranty for customers after 1EMS-ERP is practically applied.

- The warranty period will be carried out correspondingly, depending on the scale and number of modules deployed.

- When the warranty period expires, customers can sign a maintenance contract for us to continue operational support.

SUCCESS STORY

Rapid revenue growth, manufacturing expansion, unimaginable profifit

PIMA COMPANY: ENHANCING MANAGEMENT - BREAKTHROUGH SUCCESS

1EMS-ERP implementation brings breakthrough efficiency

1. PIMA’S CONTEXT

Time: Year 2020.

Sector: Plastic board manufacturing and distribution.

Scale: 200 personnel, 2 factories, 4 warehouses.

Management status:

- The company operated with disconnected software, with most processes depending on Word and Excel.

- Operations depended on key employees, making transitions difficult when they resigned.

- Customers increased, but management faced many difficulties and a high risk of loss due to lack of control, which made the Board of Directors worried about manufacturing expansion.

The Board of Directors decided to replace the system with a modern management method..

The Board of Directors decided to replace the system with a modern management method..

Director of Pima Company

Mr: Pham Thanh Phuong

Director of Pima Company

“1EMS-ERP has contributed to helping Pima company develop quickly and efficiently, while encouraging employees to work professionally and scientifically”

2. TRANSFORMATION PROCESS

- With vision and clear leadership, Pima’s Board of Directors has restructured the entire company and chosen the 1EMS-ERP solution to manage all company operations on the same unified data sharing platform.

- From the initial challenges, Pima quickly achieved results with suitable solutions.

Challenge

- Fragmented data, mainly manual management.

- Information exchange between departments mainly by message.

- Reports done manually using Word or Excel.

- No control over raw material and goods inventory.

- Production according to orders was often delayed.

Solution

- Paperless Office.

- HR - Administration Management.

- Financial - Accounting Management.

- Production Management.

- Sales Management.

- Purchasing Management.

- Warehouse management of raw materials and finished products.

Breakthrough results

- Expand production by more than 100%.

- Revenue increased by 80%.

- Management costs reduced by 30%.

- Time for signature and approval is reduced by 80%.

- Sales and inventory are controlled in real time.

- Report completion time is significantly reduced.

We are committed to our customers

FirstEMS ERP's real capabilities

100% Modules connect together with core ERP

Full REST API for other systems to connect

Compatible with business development scale

Using technology to bring efficiency

Quickly resolve system problems

Ready to join the community of success?

Our team of experts is ready to assist you in selecting the most suitable plan and deliver a live demonstration of the system’s features.