FirstEMS ERP Standardize production – Improve productivity – Ensure safety. FirstEMS ERP Standardize production – Improve productivity – Ensure safety

FirstEMS ERP Chuẩn hóa sản xuất - Nâng cao năng suất - Đảm bảo an toàn. FirstEMS ERP Chuẩn hóa sản xuất - Nâng cao năng suất - Đảm bảo an toàn.

PRD – PRODUCTION MANAGER

Control progress, enhance quality, automatically calculate cost

Manufacturing process management model

Factory

FirstEMS ERP is the optiomal solution for production management

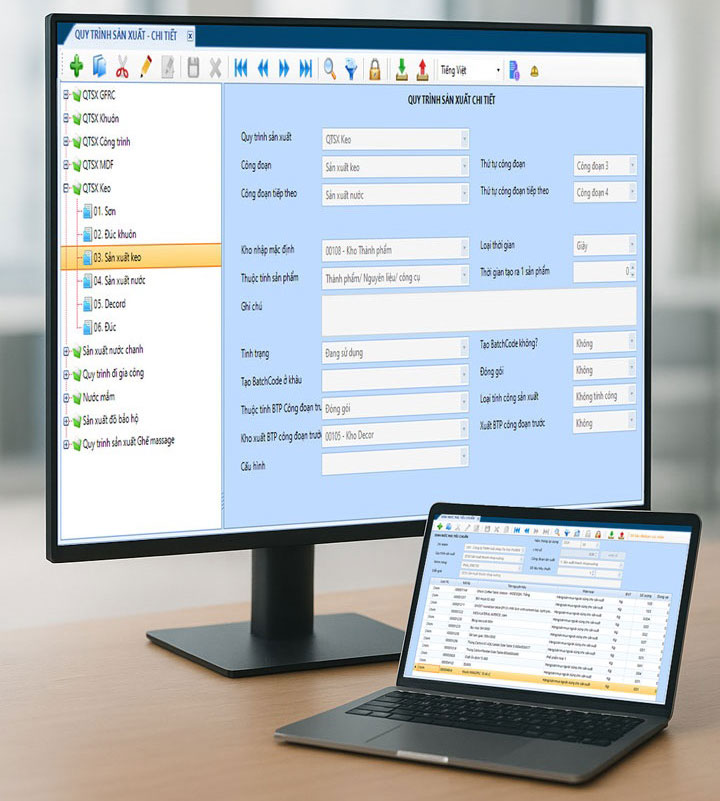

1. Manage production processes and stages

- Manages the production process for each product type, including multiple stages.

- Can record or not record stage results, for production deployment convenience.

- Consumption norms for machine hours, labor, and materials are also set for each stage.

2. Manage production capacity

- Records the quantity of machinery, labor, and skills, helping to determine maximum production capacity.

- By combining maximum production capacity, the production plan, and current orders, it determines whether new orders can be accepted.

3. Optimize material planning

- Automatically generates raw material purchasing plans, based on the Production Plan, inventory levels, norms, and supplier capacity.

- Statistical analysis of raw material prices helps the company conduct raw material purchasing most effectively.

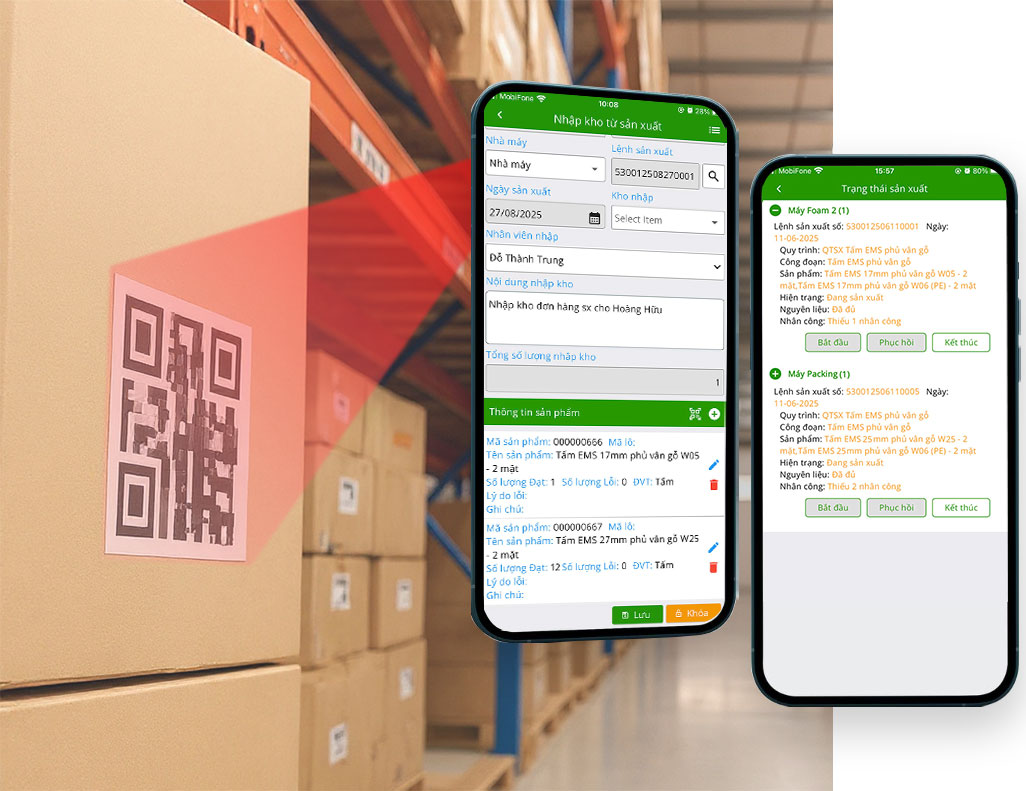

4. Execute and Control production progress

- Uses QR Code to manage: Production lines,labor, materials, finished goods.

- Checks: materials, machinery, labor before production execution.

- Records incidents in the production process.

- Updates the results of each stage into the system, potentially using QR Code and App.

- Automatically summarizes production progress results by production order.

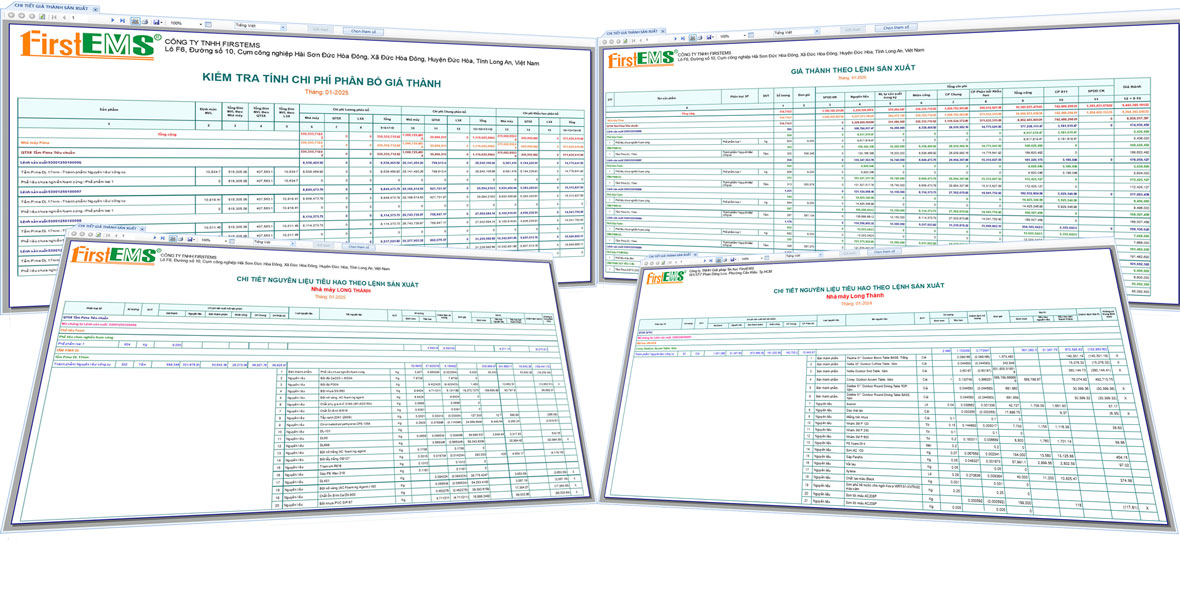

5. Automatically calculate product cost

- Manufacturing overhead is calculated automatically through the depreciation and allocation of assets and tools.

- Direct labor cost is transferred from the payroll system.

- The warehouse system determines the value of materials used, returned, and finished goods received.

- Easily allocates these costs by: Factory, Process, Stage, or Production Order.

FirstEMS ERP will automatically calculate product cost quickly and accurately.

FirstEMS ERP will automatically calculate product cost quickly and accurately.

6. 1EMS-ERP implementation process

Clear, scientifific, practical

1 Preliminary survey and overall assessment through work.

2 Quotation, negotiation, and contract signing.

3 Detailed survey of all related activities.

4 Discussion and consensus on each business process.

5 Adjusting the system to meet the agreed process.

6 System configuration, installation, and testing.

7 System re-adjustment if there are any inadequacies.

8 User training on system usage.

9 Cleaning and updating catalogs and opening data.

10 Application, contract acceptance, liquidation, and warranty.

Infrastructure for 1EMS-ERP System

Depending on the scale and requirements, the business can use one of the following two methods to deploy the infrastructure to run 1EMS-ERP.

Rent a server on the cloud.

Self-equip a dedicated server for the business

Warranty - Maintenance

- We will perform system warranty for customers after 1EMS-ERP is practically applied.

- The warranty period will be carried out correspondingly, depending on the scale and number of modules deployed.

- When the warranty period expires, customers can sign a maintenance contract for us to continue operational support.

We are committed to our customers

FirstEMS ERP's real capabilities

100% Modules connect together with core ERP

Full REST API for other systems to connect

Compatible with business development scale

Using technology to bring efficiency

Quickly resolve system problems

Ready to join the community of success?

Our team of experts is ready to assist you in selecting the most suitable plan and deliver a live demonstration of the system’s features.