INV - INVENTORY MANAGEMENT

Accurate visibility, fast issuance, automatic cost of goods sold calculation

![]() Standardizes import/export processes, automatically connects data with: Purchasing, Sales,Accounting, Production,... helping to reduce data entry and create consistent and accurate information.

Standardizes import/export processes, automatically connects data with: Purchasing, Sales,Accounting, Production,... helping to reduce data entry and create consistent and accurate information.

![]() In production, tracks consumed and excess materials by: factory, process, stage, production order, real-time inventory, helping to reduce shortages & surplus, and increase inventory turnover.

In production, tracks consumed and excess materials by: factory, process, stage, production order, real-time inventory, helping to reduce shortages & surplus, and increase inventory turnover.

![]() The system automatically calculates Cost of Goods Sold (Weighted Average, FIFO...), and carries

The system automatically calculates Cost of Goods Sold (Weighted Average, FIFO...), and carries

forward the quantity & value at the end of the period.

INV Functions

- Import data from supplier

- Return surplus materials to warehouse.

- Sales return receipt.

- Receipt from other sources.

- Raw material issue for production.

- Raw material issue return to supplier.

- Goods issue for sale to customers.

- Internal use issue.

- Warehouse Transfer Issue - Receipt.

- Inventory Count / Adjustment.

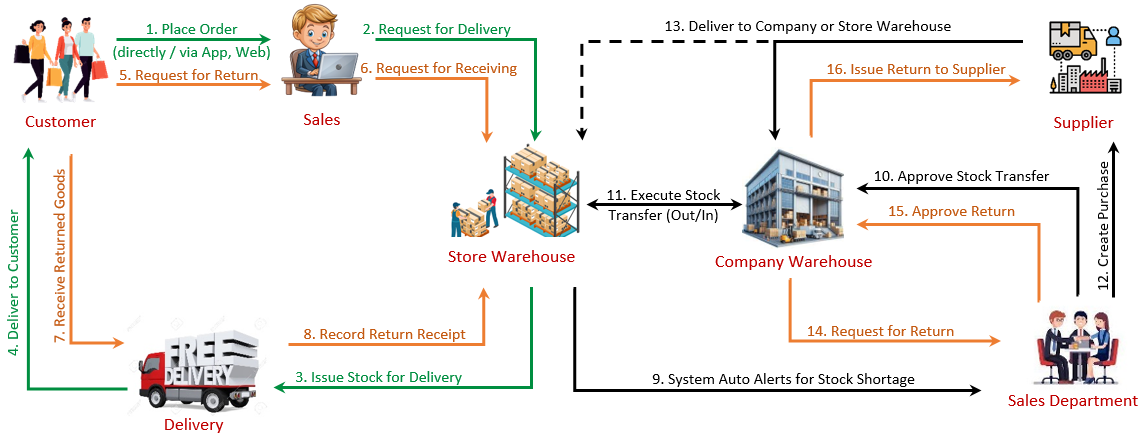

INV - Inventory Inbound and Outbound Operations

INV Highlights

- Flexible warehouse setup for management needs.

- Use of multiple units of measure in operations.

- Use of barcode, QR Code in inventory management.

- Fast, accurate inventory check using the phone.

- Auto-calculates COGS and ending inventory

- Controls inventory by Code, Batch, Date & Designation.

- Tracks inventory by warehouse location.

- Provides full reports for effective inventory management.

We are committed to our customers

FirstEMS ERP's real capabilities

100% Modules connect together with core ERP

Full REST API for other systems to connect

Compatible with business development scale

Using technology to bring efficiency

Quickly resolve system problems

Ready to join the community of success?

Our team of experts is ready to assist you in selecting the most suitable plan and deliver a live demonstration of the system’s features.